How do we make your Personalized Engagement Ring?

Each ring tells a unique story. Behind every tale there is a talented storyteller, an architect who will shape dreams into glittering reality. The creative genius is Francesco Bon, an expert gemologist and jewellery architect.

Francesco is more than just a gem expert, he is a visionary who transforms his clients’ wishes into beautiful wearable works of art. His approach is an engaging and personalized journey, which begins with an authentic and in-depth conversation with the customer.

From the beginning, Francesco immerses himself in the world of the client’s dreams and aspirations, listening carefully to their needs and desires. It’s a process driven by his mastery of gemology and his ability to create breathtaking jewels.

From choosing the gemstones to designing the ring, every step of the creation process is imbued with creativity and expertise. And in the end, thanks to his extraordinary ability to combine gemological knowledge and architectural talent, Francesco transforms his clients’ visions into extraordinary jewels that tell stories of beauty and individuality.

1. Diamond Selection

The selection of the diamond is a crucial and delicate moment, as it defines the beauty and value of the jewel. Here at Bon Gioielli, we consider it essential to listen carefully to the needs and desires of each customer. Whether it’s a diamond for yourself or your loved one, we begin this process with a deep understanding of the customer’s preferences.

First of all, we carefully research the client’s budget and preferences, which include the choice between natural and laboratory diamonds. We offer expert advice regarding diamond color and clarity, suggesting options that best suit your preferences and budget.

One of the aspects on which we do not compromise is the cut of the diamond, crucial for beauty and brilliance. We only recommend diamonds with cuts that reflect the utmost perfection.

To ensure transparency and trust, we provide gemological certificates issued by renowned institutes such as IGI and GIA. We also offer 360-degree videos that show every detail of the diamond, allowing the customer to examine it carefully.

The prices are always clear and justified, and in case the customer has any doubts or questions, we are always available to continue the research until his full satisfaction is achieved.

Once the diamond choice has been made, we enter the CAD design phase, where our experts work carefully to transform the customer’s vision into a detailed and accurate drawing. This is just the beginning of the journey towards creating a unique and unforgettable jewel from Bon Gioielli.

2. The Design

In the design phase, we pay particular attention to actively listening to the customer’s preferences, in order to propose the ideal solution that perfectly reflects their vision of a perfect ring. Furthermore, we offer a unique service: we send a ring holder to the customer’s address free of charge, which allows you to comfortably test the size of your finger at home. In case the ring is a surprise gift, the ring holder will be included in the package, to facilitate resizing.

During the design phase, we discuss every detail with the customer, from the type of setting (solitaire, pavé, hallo or band) to the color of the metal. All this information is then brought to our Fonte Nuova headquarters, where our CAD technical expert, David, takes care of the design.

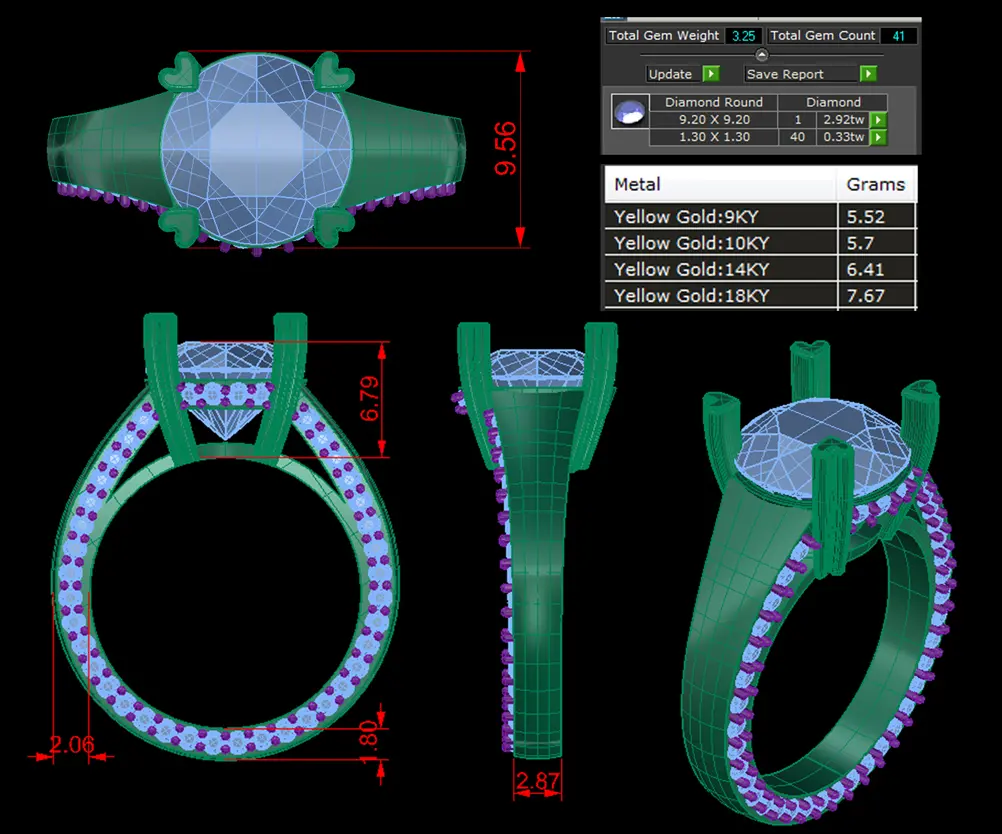

CAD plays a crucial role in two key aspects of the process. First, it is used to create a photo or video rendering of the final ring, including information such as the weight of the gold and the number and carat weight of the side or outline diamonds. This allows the customer to know in advance the cost of making the ring, avoiding unpleasant surprises. The customer can accurately evaluate the product and confirm his choice, having clear information on the cost before proceeding. Second, the CAD is sent to our foundry, which prints the exact wax rendering model the same day. This process guarantees maximum fidelity to the original design. The next day, casting is performed based on the wax model. Next, we move on to finishing the blank frame, to ensure every detail is perfect before proceeding to the next stage of the manufacturing process.

3. Craftsmanship

After the rough casting, our team of specialized goldsmiths goes into action to give the setting the artisanal perfection that characterizes each of our jewels. With care and skill, they finish and polish both the inside and outside of the ring, ensuring that every detail shines with beauty. During this phase, the goldsmith Alessandro carefully checks the ring’s measurements and, if necessary, makes any corrections to ensure a perfect fit. Every detail is carefully taken care of, because we know that even the smallest detail can make the difference. Once the finishing phase is completed, the semi-finished ring is delivered to the skilled hands of our exceptional setter, Gianni. He is the creator of magic, whose task is to combine the selected stone with the desired ring. Carefully following the customer’s preferences, Gianni checks the height of the diamond and the finishing of the tips that support it, making sure to faithfully follow the rendering image. This approach ensures that the customer does not have any unpleasant surprises when receiving their jewellery. After the setting work, the ring passes to the expert hands of our cleaner. It is he who takes care of polishing the ring, giving it a final shine before its presentation to the customer. Each step of the manufacturing process is performed with care and dedication, with the aim of creating jewellery that is true masterpieces of craftsmanship and timeless beauty.

4. The Engraving

After the cleaning process, the ring goes through another customization phase in Sandro’s skilled hands. An expert engraver, Sandro adds that final touch of personalization to the already polished ring. Using precision laser techniques, he expertly engraves the patented Bon Gioielli logo, the name of the line, and the gemological appraisal number that accompanies the ring. But Sandro’s art doesn’t stop here. He will take care of engraving any customization requested by the customer, be it a special date, a name or a significant phrase. With the help of the best laser engraving machine on the market, Sandro transforms each jewel into a unique and memorable piece, which reflects the history and personality of its owner.

5. Rhodium plating:

Rhodium plating represents the last phase of the production process of our ring, a crucial moment that gives that final touch of refinement and brightness. It is a galvanic process in which rhodium is used, a rare metal with a silvery-white hue which gives the jewel an unparalleled shine. During rhodium plating, the thin layer of rhodium is applied to the surface of the ring, transforming the yellow gold into a lustrous white metal. This process not only gives the jewel an aesthetically flawless appearance, but also increases its durability over time, protecting it from oxidation and wear. Once the rhodium plating is complete, we can finally consider our ring as finished and ready to be delivered to its recipient. Every detail has been taken care of with attention and passion, from the moment of diamond selection to the final rhodium plating phase, guaranteeing a superior quality jewel that will be appreciated for generations.